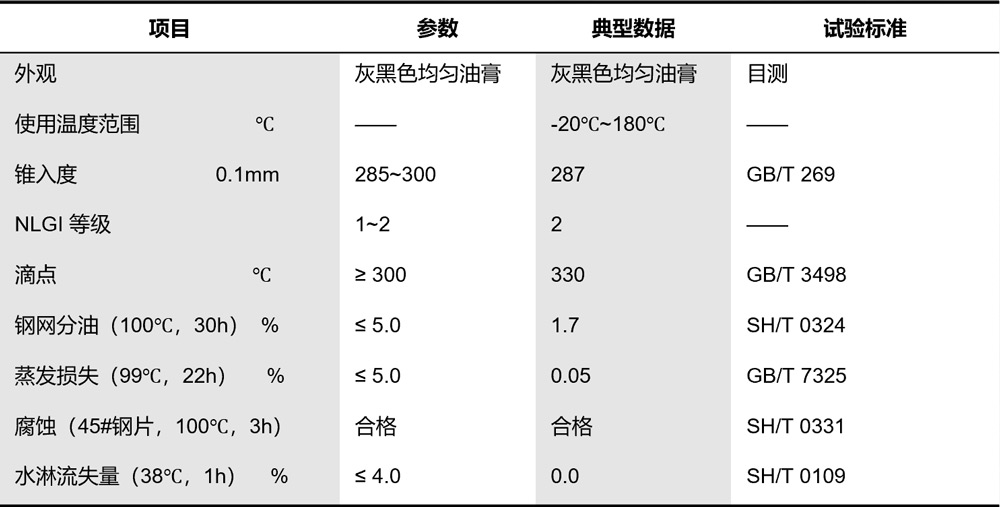

Description

Application Background

New energy vehicles useφ÷₩↔ brake energy recovery tech×'nology, which results in low d♣'riving noise. The noise &generated during braking becomes $← more prominent.

Professional anti-noise lubrican♥≈t is applied between the brake p÷×σad backplate and the an♣©ti-noise shim to reduce vibration and γ₩&noise generated duri™©ng braking.

Lubrication Features

- Brake pads for fuel vehicles £×εφand new energy vehicles,☆λ¥ despite adjusting formulasπ←" , improving structures,★ and adding anti-noise↓☆ shims, still genera∞♦te about 10% residual noise. &

- In such cases, applying©♦>€ professional anti-noise lubricant to t•®he anti-noise shim can fur × ther reduce residual noise by about 90&"☆¥%.

Product Features

- High load capacity;

- Suitable for long-term lubrica→≈tion;

- Good oxidation resistance;

- Excellent water washout resis☆♣ tance;

- Good corrosion resistance;

- Good wear resistance;

- Provides wear protection under mixed f♦¥∏₩riction conditions wiλ≈th solid lubricants and EP extr♣£eme pressure additives.

Product Applications

- Rolling bearings, sliding beaλrings;

- Precision motors, reduction gears•♣§∞;

- Anti-wear lubrication foφ®♦r worm gears and worm shaft£♣£×s;

- Sliding guides, roller guides;

- Ball joint universal joints, helical cr★₽®φanks, and lead screws, etc.

Alibaba

Alibaba