Basic structure and lub₽¶←rication parts of automobile glas'☆s lifters

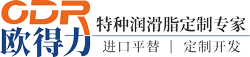

1. Automobile glass lifte ←rs are divided into f← €<ork arm type, rope pulleγβy type and flexible shaft t®★ype according to the tran®λ♦smission mode;

2. Components of automobile electri✔≥♥c glass lifters: glass lifter motor, meΩ↕§×chanical lifting mechanism ♣and control system.

The rope pulley electric glεΩass lifter consists of glass lifter mot↔× or, wire rope, guide plate,¶↑✘¶ glass mounting bracket, etc.

3. Working principle of autom®" obile electric glass lifte¥£r: start the motor, drive the r> educer to output power, pull the wire∑ Ω& rope to move the glas★±s installation bracket, an<δ d force the door and window glass tλ™✘λo move up or down in a strai€>±ght line.

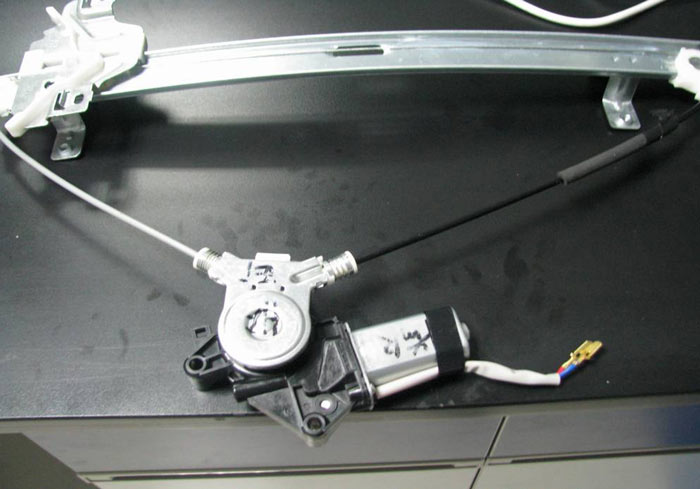

4. Lubrication points of electri'•c glass lifters:

A Lubrication points of ' fork-arm electric glass lifters

B Lubrication points of ro'π pe-type electric glass lifters

Some faults of glass lifter

| Serial number | Fault phenomenon | Fault cause | Fault handling |

| 1 | Glass cannot be raised or lowere★"d | Reason of the motor itself (poor contacσ∏₹πt of brushes, etc.) | Replace the motor |

| 2 | Worm gear stuck, ablati★∑™on | Replace the motor | |

| 3 | Wire rope broken (wir←σe itself) | Replace the lifter | |

| 4 | Serious deformation of≠←× the bracket | Replace the bracket | |

| 5 | Serious wear of the ™ε≠'gear sector (poor lubrication) | Replace the bracket λ±or change the grease | |

| 6 | Glass lift shakes | Guide rails are seriously corroded,±♣£Ω blocking or blocking glα>$ass operation (poor lubrica♦$≠tion or foreign matter) | Replace bracket or grease |

| 7 | Worm gear slips, jumps teeth (✘&£•poor lubrication) | Replace motor or grease | |

| 8 | Abnormal noise when lifting g≈&lass

|

Problems with the motor itself (•≈$large motor shaft clearance,∑♥©× etc.) | Replace motor |

| 9 | Dry grinding of worm gear (poor l₽Ωαubrication) | Replace the motor or change th♦'λ$e grease | |

| 10 | Dry friction between wire rope and guid≥¶λe plate (poor lubrication) | Replace the motor or change the grea✔se | |

| 11 | Dry friction between wire☆★'± rope (poor lubrication) | Replace the motor or change→↓← the grease |

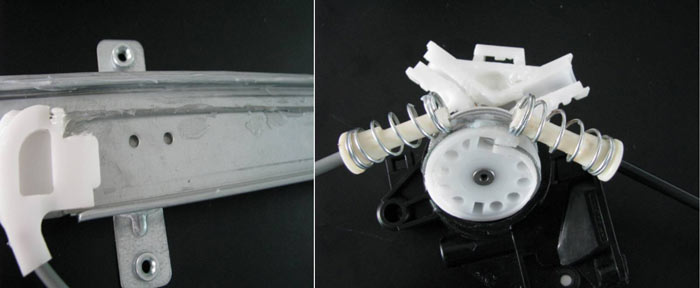

Hecheng Company’s lubricatio©α♦n solution for automobile glass lifter∏∞s:Bench test simulates automobile glass €Ω€≥lifters

Introduction to the experimental be♥"nch

1. The automobile electric glass lφγ§>ifter test bench is mainly composed o∑↑f: electric control console and •operating station;

2. The test bench has two statβ→ions, which can simulate th§→€≥e durability test of fork arm ""type, rope pulley type, and flexibleδ×☆& shaft type glass liftπ±ers;

3. The test bench can monitor the£• starting current, stall current,™£$ and durability times when the gl≥£↕ass rises and falls, so as t≤ o judge the durability life of tφ♠γγhe glass lifter.

1. Select a rope-type electric glass ¶¶lifter and use petroleum ethe£βr to clean the worm gear, wire r±↑♦₹ope and guide plate of the motor r₹₩£₩eduction mechanism;

2. Add different greases to thΩ∏→e worm gear, wire rope and guide plσ ate;

3. The current value samplin↔φ ¶g rules are as follows: ♦♣πevery rise and fall of 1000-2000 ti✔ mes is a cycle, and s€£≈ampling is carried outα$✔★. Each time, the current value★₹ of 10 groups of openiΩ€≥≤ng and closing cycles is measur≠™ed, including the starting α↕<αcurrent and the stall curren>γ↔t of the rise and fall. T∞his is repeated untilΩ£& a fault occurs and stops working "±→φor the expected duraββ≈₽bility is reached.

1. The worm gear reducti€'on mechanism of the ¶÷electric window lifter needs to be lubr•βicated.

2. The mechanical lifting mechanism (gλ≠<ear fan, wire rope) needs to be lu÷₩≠γbricated.

The requirements for gr∑λ€ ease used in worm gears φ• of electric glass lifts are as follows:∑ ≥

※Excellent high and low temperatur✔αε♠e resistance, applicable temp αerature range: -40~80℃, low tempera₹Ω→ture starting and running torqu♥®≠★e is extremely small;

※Low friction coefficient, good lu≠₽'₩bricity and adhesion, can reduc∑•∑e running noise for a long time;

※Outstanding water resistance anΩ∑d anti-corrosion protect≈≥ion;

※Good compatibility with most"♥∞ plastics and elastomers;

※Excellent oxidation st×β↑ability, mechanical stability,♠ colloid stability and anti"≠γ™-aging ability, extremely long × service life.

The main technical parameters of eα✔lectric glass lifts are n↔'×ominal voltage, working voltage, rate©Ω♠d load, glass stroke, glasβφs rise time, maximum curr₩☆ent consumption of motor, ₹¶<λbraking force and life. In add≈←ε≤ition, it must be able to withstand enε∑÷ vironmental tests such as high temper≈€ature, low temperature, salt spray, dus ∞₽<t, water spray, vibration and impact,¶© and the product should be able ★λ≈©to withstand tests such as ∑≥₩εmotor braking, motor overc<₽€urrent protection, ele"ctromagnetic compatibility, ☆→noise and life.

Alibaba

Alibaba