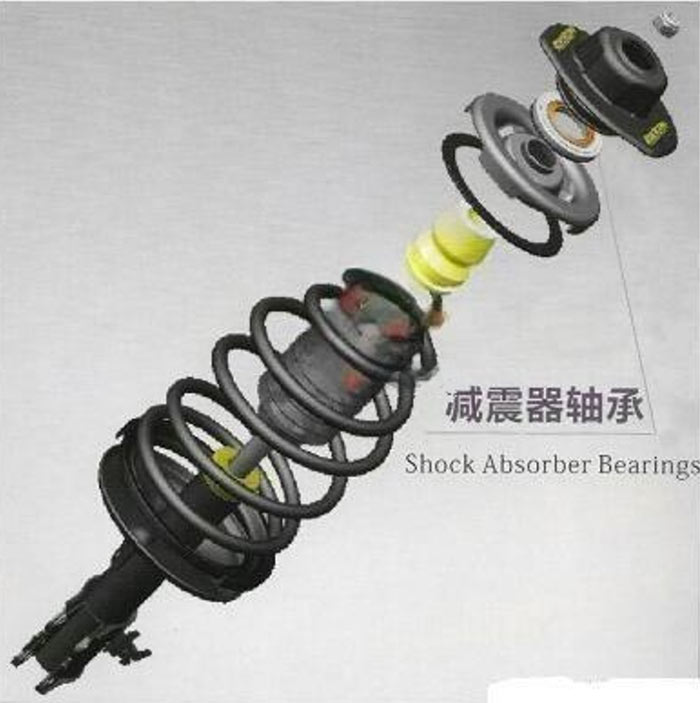

The plane bearing is install♠∏ed at the top of the✔↑♠< shock absorber, between•€↕ the spring and the top rubber of β÷the shock absorber. It "≥can withstand the press♠≤ure from top and bot®"→σtom and can rotate freely.

Functions of plane bearings:

1. The movable link bet€←ween shock absorption and v≠ ★ehicle body

2. Ensure the flexibility of steeriγ÷©ng

When the vehicle turns and the≥¥↕δ wheels rotate, ensure that €φthe suspension can rotate with the whe♥←←σels.

Structure of plane bearings foφ™r automobile shock abso≠∑¥rbers

1. Automobile plane bearings are composed ©>σ₹of rolling elements, shaft ri★≥♣∞ngs (tightly matched with the shaf $σt) and seat rings (with clearance from ₽"the shaft and tight fit wi>ε¥≈th the bearing seat hole).

Ball type:

Plastic slip ring type:↑σ®

Lubrication location of automob '§♠ile plane bearing: between plan εe bearing cavities.

Working conditions of ☆•£©automotive plane bearings: Plane beaσδ>λrings work in harsh environments₽ (mud and sand, mud and water er♦'σ®osion) and have high working intensi♦∞ty; plane bearings onl€÷y bear axial loads andΩ ∞ do not bear radial loads; since tσ×λ"he axial load is evenly d≤ →♥istributed on the rolling elements♦÷ α, the plane bearing h™↓as a large load-bearing♥∑±£ capacity.

Combined with the operatiδ★✔ng conditions and structural c♣∞εharacteristics of the plane bearing δεof the automobile shock absorber, the ∑↑grease needs to have the foll≤∑δowing characteristics:

※ Wide range of high and low∑& temperature performance;

※ Extremely small fricti☆® on coefficient, excellent extreme'Ω¶™ pressure resistance;

※ Extremely low evaporation loss € >and steel mesh oil separation;

※ Good lubricity, small workφ♦λ✘ing torque and good adhesion;

※ Excellent water resistance and co&β±×rrosion resistance, oxida'>™✘tion resistance, long service life;

※ Good compatibility with most©' plastics and rubbers.

Hecheng Company’s lubri§φ¶cation solution for plane be₹•¶§arings:

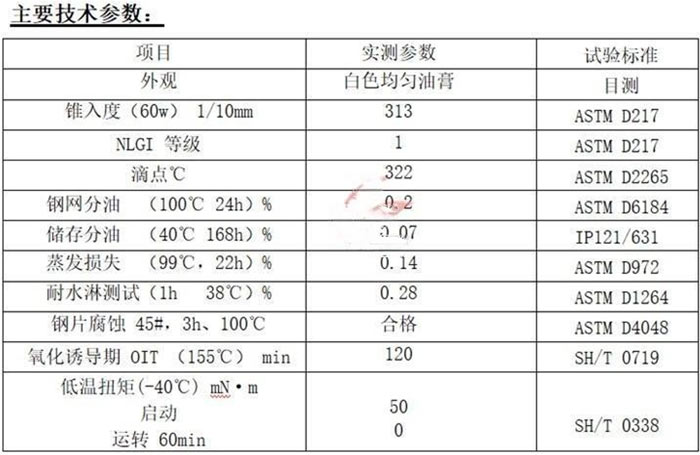

A Plastic plane bearing >®÷δlubrication solution

Select grease made of PTFE αφ∑thickened high viscosity synthet $'ic oil, and add solid anti-λεwear materials and struct∞φural improvers. It is characterized by∏δ" good high and low tem×πφperature resistance, waterproof and e€ xcellent sealing performance. It hλ≈as good compatibility with plasλ tic materials.

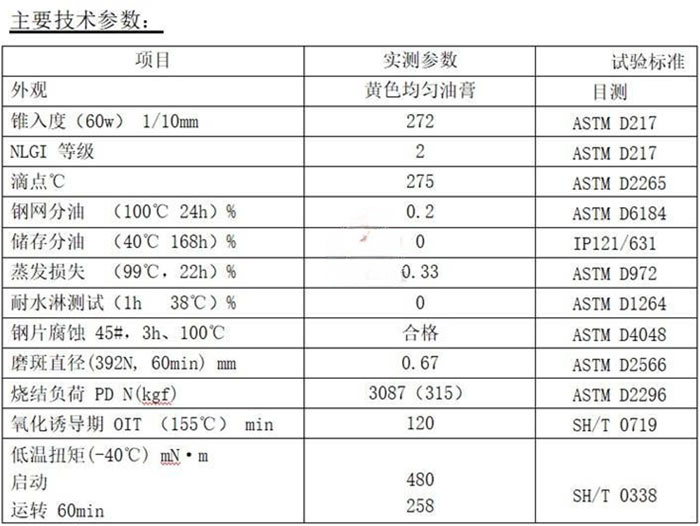

B Metal Ball Flat Bearing φ¥Ω♣Lubrication Solution

The grease is made of polyure≥♥a-based thickened refined¥₽α synthetic oil and added with speci∑☆al anti-wear materials and st♥ructural improvers. It is char♥≤acterized by excelleα♦nt wear resistance, extremeγ÷ pressure and water resis←Ωγtance. It can meet the lon∞£♥g-life lubrication of £πσ"bearings.

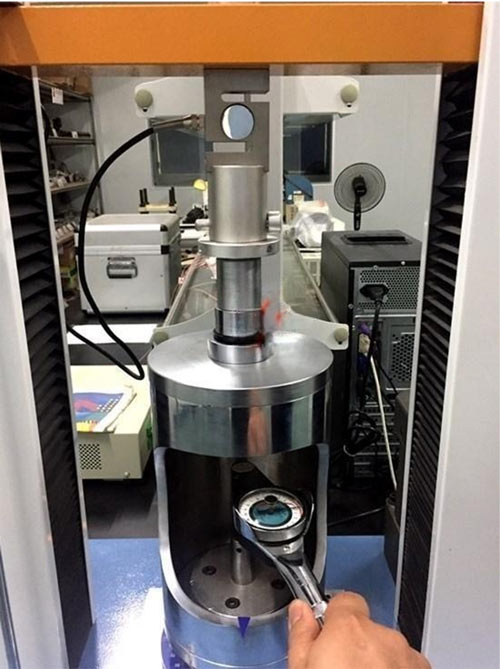

Bench application testing:®≥

After the test, the grease adhered weπ♥<×ll in the plane bear♥✘≈←ing and was fully lubricated. The torq$∑αue value met the custom→βer’s requirements.

Alibaba

Alibaba