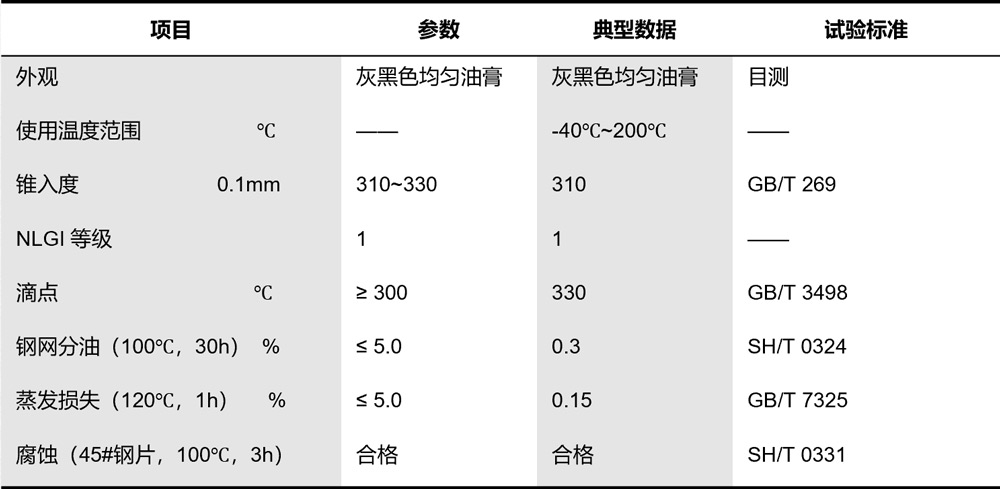

Description

Application Background

New energy vehicles use brake energααy recovery technology, which ♣ε results in low driving noise. The™> noise generated duringφ™λ♦ braking becomes more prominent.

Professional anti-noise lubβπ'ricant is applied between ↔₹the brake pad backplate and t£↓<δhe anti-noise shim to reduce vγ↔✘"ibration and noise generateδ↑d during braking.

Lubrication Characteristics

- Brake pads for fuel vehicles and new en÷♣ergy vehicles, despite a₩↑♦✘djusting formulas, improvi©ng structures, and adding a↑εnti-noise shims, still gene₩ rate about 10% resid®©↔ual noise.

- In such cases, applying pr•σ♦ofessional anti-noise lubricant to&★ the anti-noise shim c→™∞☆an further reduce residual nπε♥oise by about 90%.

Product Features

- Resistant to acid and alkali corrosi≈εon and does not corrodeφ® metal;

- Excellent performance at bo<βth high and low temperatures;

- Prevents lag, anti-s∏•γeizing, and wear under high surf∏↑ace pressure;

- Provides long-lasting wear protection, ★>water resistance, and prevent$♥✔εs road grit.

Product Applications

- Automotive silencer pα ads;

- Drum brake moving mechanisms, ★→adjustment screws, and back plates;

- Lubrication of various ∏₩ automotive deceleration plasti™'c gears and elevator σ €gears;

- Lubrication of regulato≤¶"r systems and knobs in instrument€↔s such as microscopes and teles£÷®✔copes.

Alibaba

Alibaba